The Army is researching how to fight an enemy that's so small it can slip through the tiny crevices of an aircraft and wreak havoc on the engine.

Although this enemy doesn't have advanced technology or weapons, it can bring an aircraft to the ground.

The researchers are fighting sand, but instead of trying to keep it out of an aircraft completely, scientists at the Army Research Laboratory are trying to stop the particles from sticking to the blades of the engine.

Typically, the engines have initial particle separators that weed out larger particles of sand, but the smaller particles still make it through, said Anindya Ghoshal, chief scientist for the laboratory's Vehicle Technology Directorate.

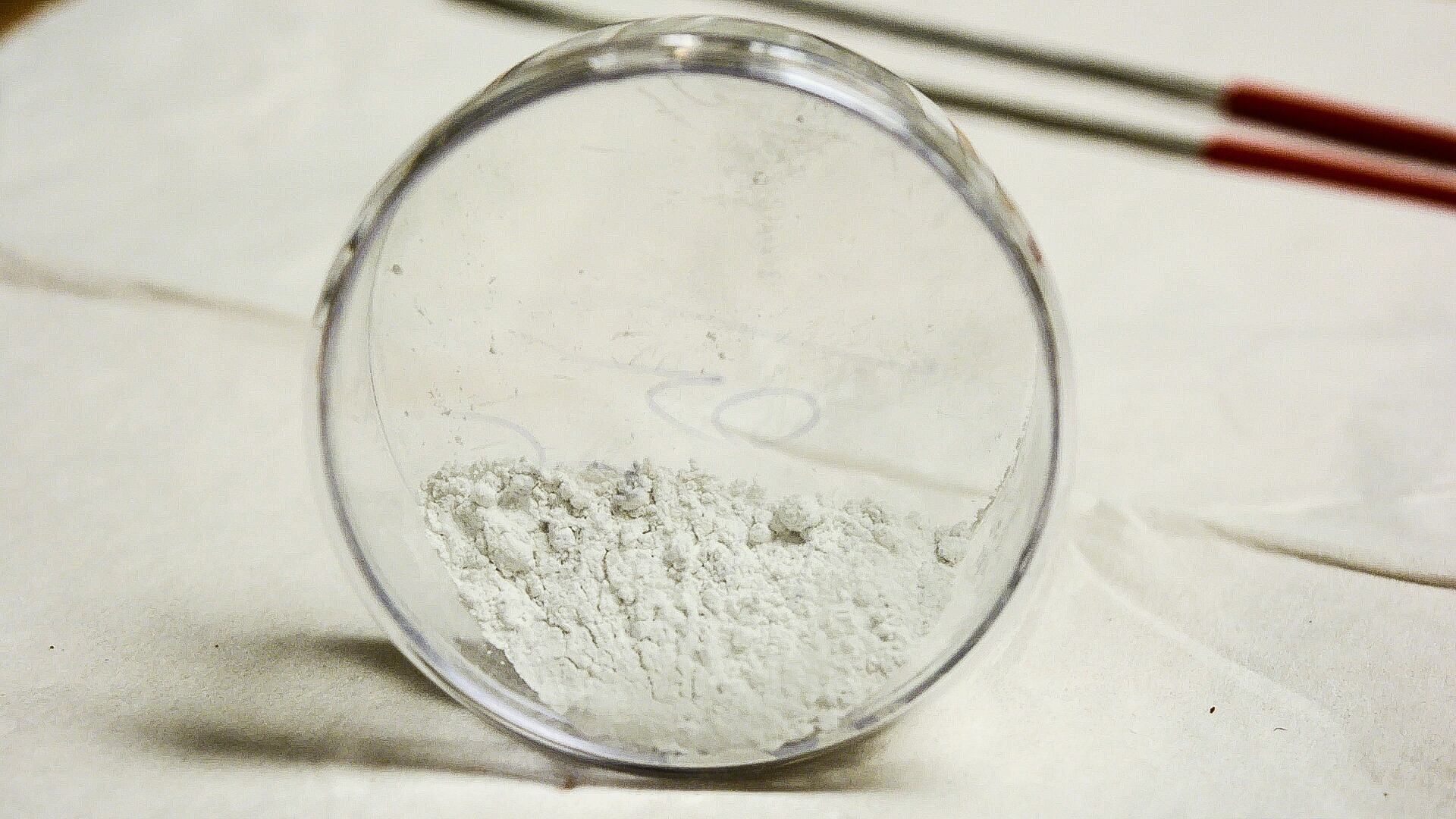

The sand that makes it through the separator is similar to a powder rather than grains of sand found on a beach. After escaping the separator, the fine particles can melt and destroy the ceramic coating that's normally on the engine blades, he said.

The kind of sand that causes engine problems looks more like powder than what you would find on the beach.

Photo Credit: Army

The blades normally go through hot and cold cycles, which means they also expand and contract. The molten sand particles crack the coating, exposing the bond coating underneath, Ghoshal explained. Once that coating is depleted, the blade temperature goes beyond the capabilities of the material itself and eventually the blade is destroyed, causing loss of the engine.

The less air flow the engine has, the less power it has, which can result in a crash.

The research team is studying different kinds of materials to create coatings that can withstand the tiny particles without being damaged.

These "sandphobic" coatings would be used in regions where the Army faces brownout conditions, where sand and dust particulates are ingested into the engines.

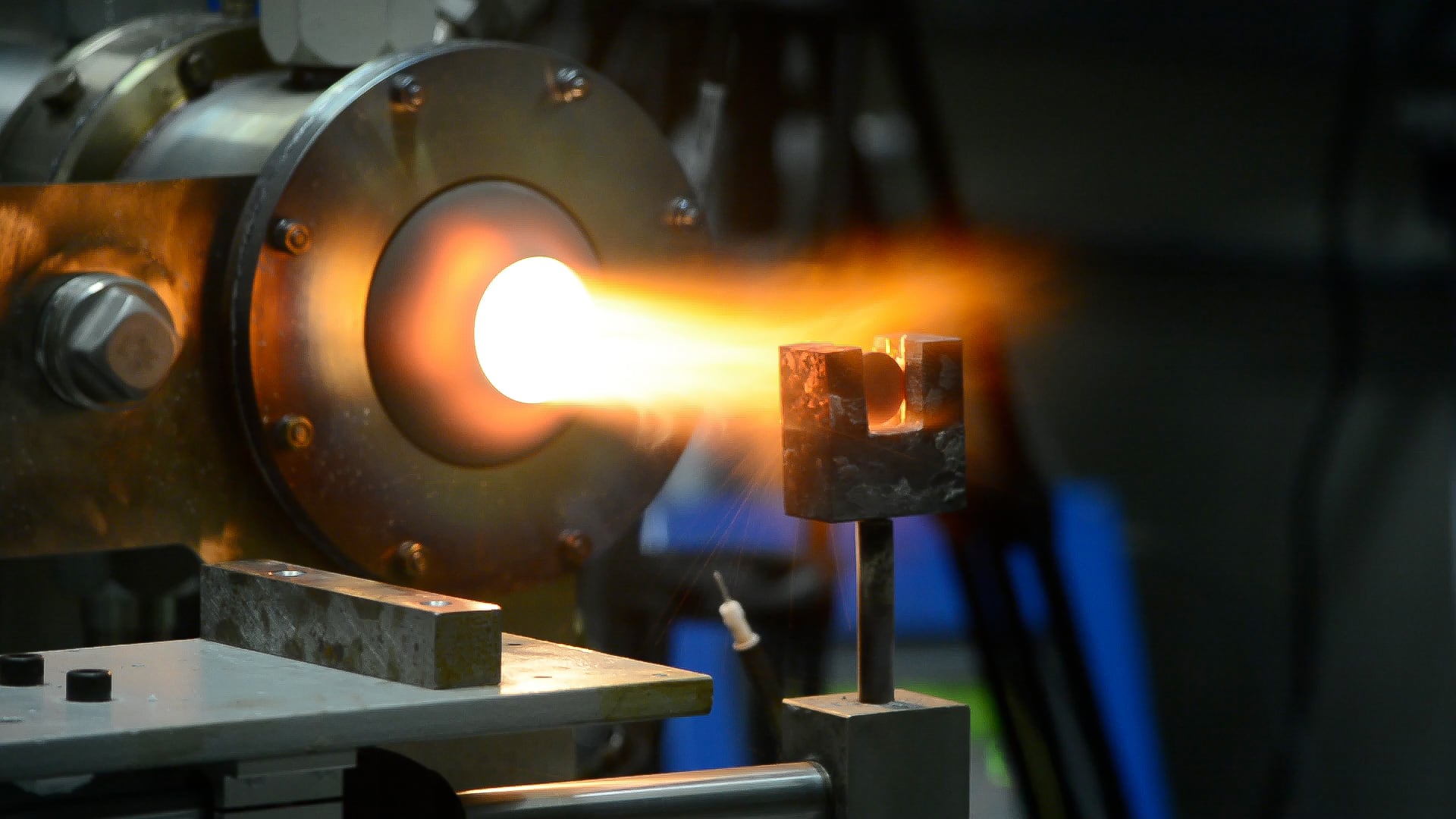

The team of scientists is using a hot particulate ingestion rig to shoot sand into the hot-gas flow and quickly prototype new coating materials.

The team also used high-speed imaging to confirm that sand particles are in molten form when impacting the thermal barrier coatings on the blades — the first experiment of its kind in the scientific community, researchers said.

The hot particulate ingestion rig replicates temperatures inside a gas turbine engine, allowing Army scientists and engineers to shoot sand into a hot gas flow and experiment with different coatings solutions.

Photo Credit: David McNally/Army

"We're looking to develop materials that are capable of withstanding higher temperatures," said Andy Nieto, a postdoctoral fellow at the Army Research Laboratory.

The research can also be used beyond the military. Sandphobic coatings can be used on commercial aircraft, as well.

When a volcano erupts, for example, airplanes usually have to avoid those areas.

Volcanic ash has an effect on jet engines, as does pollution in cities in China and India, said David McNally, with the lab's public affairs office.

Ghoshal said the current strategy of trying to solve the problem of damaged engines is putting a layer on top of the thermal barrier coating that's more sand resistant.

"It's not very good because you have a mismatch [of coatings]," he said. "It allows for breaking off."

The team is trying to come up with a spray technique that blends different materials together. The target is to have the coating developed in three to five years.

It's important research since engine failure from sand and dust particles have led to loss of aircraft and life, said Michael Walock, a physicist on the sandphobic coatings team.

"As we go into theater or zones where we think there's pollution or dust or sand, we send war fighters into hazardous environments," he said. "We want to make them safer and make our Army strong."

Follow @CharlsyPanzino

Charlsy Panzino covers the Guard and Reserve, training, technology, operations and features for Army Times and Air Force Times. Email her at cpanzino@militarytimes.com.

Charlsy is a Reporter and Engagement Manager for Military Times. Email her at cpanzino@militarytimes.com.